PTFE (Polytetrafluoroethylene) fuel hoses have become an essential component in modern automotive fuel systems. Known for their high chemical resistance, excellent temperature tolerance, and durability, PTFE fuel lines are widely used in performance vehicles, classic car restorations, and high-vibration environments.

However, even the most reliable PTFE hoses can experience leaks if proper installation, maintenance, and handling techniques are not followed.

This article explores key methods to prevent fuel leaks when using PTFE hoses.

1. Choosing the Right Hose for Your Application

Preventing leaks begins with selecting the correct PTFE fuel hose. Factors to consider include:

- Pressure rating: Ensure the hose can handle the system’s maximum pressure.

- Temperature range: Choose hoses rated for both the minimum and maximum operating temperatures.

- Chemical compatibility: Verify that the hose material is compatible with the type of fuel, additives, or other fluids in the system.

- Hose diameter: Proper inner and outer diameters prevent over-tightening and reduce stress on connections.

Using a hose that meets or exceeds system requirements significantly reduces the risk of leaks.

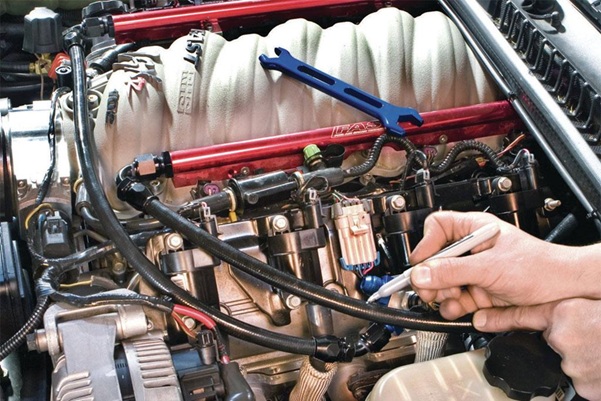

2. Proper Hose Fittings and End Connections

Leaks often occur at hose connections rather than along the hose itself. Techniques to prevent this include:

- Using compatible fittings: PTFE hoses require fittings specifically designed for PTFE, such as stainless steel or aluminum compression fittings.

- Correct crimping: Ensure crimped ends are done according to manufacturer specifications to avoid gaps or weak seals.

- Double-checking threaded connections: Use thread sealant or PTFE tape if recommended by the fitting manufacturer, but avoid over-tightening.

Properly installed fittings ensure a secure connection and prevent fuel from seeping through joints.

3. Avoiding Kinks, Twists, and Excessive Bends

PTFE fuel line hoses are flexible but can become damaged or weakened if bent too sharply. To prevent leaks:

- Maintain a minimum bend radius specified by the manufacturer.

- Avoid twisting the hose during installation.

- Use hose supports or clamps to reduce vibration and movement, which can stress connections.

Minimizing mechanical stress on the hose helps maintain integrity over time.

4. Routine Inspection and Maintenance

Even the highest-quality PTFE fuel hoses require regular inspection:

- Check for abrasion, wear, or rubbing against other components.

- Inspect fittings for signs of loosening or corrosion.

- Look for any soft spots, swelling, or fuel residue, which may indicate potential leaks.

Early detection allows preventive action before a minor issue becomes a dangerous leak.

5. Proper Cleaning and Handling

Contamination or improper handling can compromise a PTFE hose:

- Use compatible cleaning agents to avoid chemical degradation.

- Avoid contact with sharp tools or rough surfaces during installation.

- Handle hoses gently, especially during routing, to prevent microscopic cracks or punctures.

Safe handling preserves the hose’s structural and chemical resistance properties.

6. Environmental Considerations

Environmental factors like heat, vibration, and exposure to engine fluids can affect hose longevity:

- Shield hoses from direct heat sources using protective sleeves or heat wraps.

- Secure hoses to minimize vibration-induced wear.

- Avoid exposure to oils, solvents, or other chemicals that may weaken the hose material.

Mitigating environmental stressors reduces the likelihood of leaks developing over time.